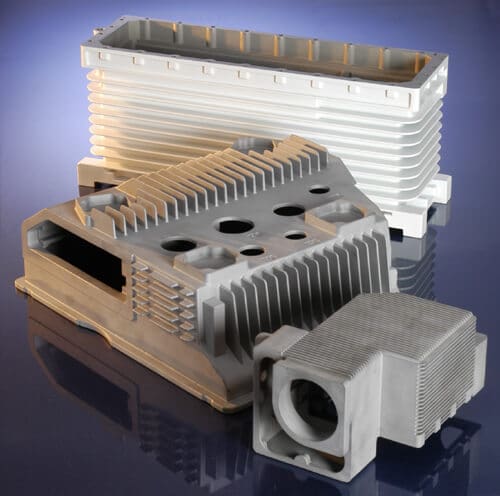

Manufacturing Design and Engineering Services at Nu-Cast

CAD services for every industry

Combine modern CAD applications with comprehensive quality control equipment for structural and thermal analysis of castings, and you can be sure that the casting you receive is underscored by quality – inside and out.

The Ultra-Light 3D Cast Truss Beam Structure

- Maximum Weight Efficiency

- Replaces Costly Honeycomb / Composites

- Monolithic Structures from Small to 50″ and larger

- High Strength / Stiffness to Weight Ratio

- Now Available in Most Cast Aluminum Alloys

- 125 RMS Finish or Better

- Cast in Any Shape, Square, Hexagonal, Contoured

- .080 – 2.50 Rod Diameters

- Custom Design for Each Application

- Structural Analysys / Math Model (Algor / Nastran)

- STL CAD File Development

- Pro E, CAD-Key, Autocad, Others

Concurrent Engineering

Review Design

Review systems and components on the basis of function, design, product ability and cost. Provide specific recommendations, alternate design approaches, and supporting rationale.

Systems and Component Design

Including optical systems, components, enclosures, structural and mounting systems, etc.

Investment Casting Design

Tolerances, Dimensions, and More

Casting and Machining

Design Recommendations

Production Drawings

Material selection

Our engineering team will define the advantages and disadvantages of a given material, while recommending the materials that will meet your the mechanical and budgetary requirements

Concurrent Manufacturing

Nu-Cast, Inc. now offers Concurrent Manufacturing, which is much more than concurrent engineering. While virtually any aluminum casting foundry can make castings from drawings, it takes a specific set of capabilities and expertise to manufacture castings without a complete set of drawings or a cad file.

While this is never ideal, many times it is the only way to help our customers achieve their goals.

Quality Assurance

NCI is an ISO 9001:2015, AS 9100:D registered international aluminum investment casting company.

Nu-Cast is a privately-held company and has been providing aluminum investment castings for commercial / industrial, aerospace and government use since 1986. Our 40,000 sq. ft. building, located at 29 Grenier Field Road, Londonderry, NH, contains offices and manufacturing facilities and equipment to produce a wide range of aluminum-based investment castings. In this facility we also have the ability to work with newer, developmental materials, for both the cast products themselves and the mold and process technologies. Our employees provide engineering, management and production skills, which are supplemented by outside mechanical and structural engineering consultants as dictated by individual project requirements.